Construction Site Footwear Guide: Safety Shoes for Impact, Puncture & Slip Protection

Upload Time:

Oct 20, 2025

On every building site, the right Safety Shoes for Construction are a worker’s most reliable protection. Construction environments are full of potential hazards—falling objects, sharp debris, and slippery surfaces. That’s why choosing safety shoes for construction with anti-impact, anti-puncture, and anti-slip protection is essential for both safety and efficiency.

1. Anti-Impact: Steel Toe and Composite Toe Protection

Falling materials and heavy tools are the top causes of foot injuries on construction sites.

Safety shoes for construction should include:

-

Steel or composite toe caps tested to EN ISO 20345 or ASTM standards.

-

Shock-absorbing midsoles to reduce impact on feet and joints.

-

Reinforced toe areas for maximum durability.

Recommended type: Steel Toe Safety Boots / Composite Toe Work Shoes.

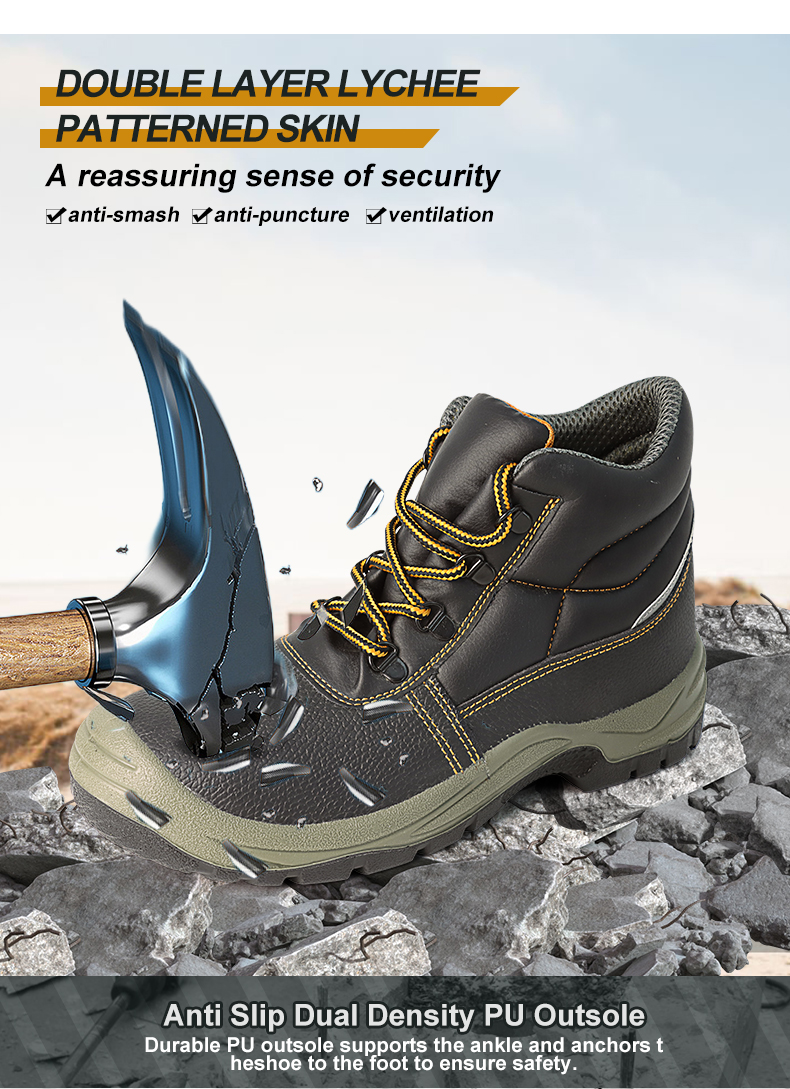

2. Anti-Puncture: Protection from Nails, Metal Scraps, and Debris

Sharp materials like nails or rebar can easily penetrate ordinary soles. That’s why anti-puncture safety shoes for construction are designed with:

-

Kevlar or steel midsoles that resist puncture up to 1100N.

-

Thick rubber outsoles for extra stability.

-

Flexible sole construction that balances safety and comfort.

Recommended type: Puncture Proof Safety Shoes / Steel Plate Sole Work Boots.

3. Anti-Slip: Preventing Falls and Accidents on Site

Construction sites are often wet, dusty, or uneven, creating a high risk of slips and falls.

Choose safety shoes for construction with:

-

Slip-resistant rubber soles featuring deep tread patterns.

-

Oil-resistant and water-repellent surfaces for grip in wet areas.

-

Ankle support to prevent twisting on uneven terrain.

Recommended type: Non Slip Safety Boots / Outdoor Work Shoes.

4. Additional Features to Consider

When selecting safety shoes for construction, consider these practical details:

-

Breathable uppers (mesh or microfiber) for long hours in hot weather.

-

Waterproof membranes for outdoor or rainy-day work.

-

Shock-absorbing insoles to reduce fatigue.

-

Reflective strips for night visibility and safety compliance.

5. Standards and Compliance

High-quality safety shoes for construction must meet:

-

EN ISO 20345:2011 (Europe) standards for impact and puncture resistance.

-

ASTM F2413 (USA) for toe protection and slip resistance.

-

CE and ISO certifications for international export and OEM supply.

Always ask suppliers for testing reports before bulk purchasing.

About Our Company – SAILGOOD Safety Footwear Manufacturer

Founded in 2013, SAILGOOD specializes in the design and production of Safety Shoes for Construction, Protective Gloves, and other PPE equipment for the industrial sector. Our products serve clients in the construction, oil & gas, logistics, and manufacturing industries.

We offer OEM & ODM customization, allowing buyers to develop their own branded safety shoes for construction with full certification support.

With advanced production lines, strict quality control, and over 10 years of experience, SAILGOOD ensures every pair delivers comfort, protection, and durability.

Welcome global distributors and partners to cooperate with SAILGOOD.

We provide samples, flexible MOQ, and fast delivery for your private-label safety footwear projects.

Conclusion

In the construction industry, workplace safety begins from the ground up.

Choosing the right safety shoes for construction—those that combine anti-impact, anti-puncture, and anti-slip protection—can prevent injuries and enhance worker confidence.

For long-term reliability, comfort, and compliance, trust SAILGOOD safety shoes—your professional partner in industrial safety.