Chemical Industry Safety: How to Choose and Replace Acid and Alkali Resistant Safety Shoes

Upload Time:

Oct 20, 2025

In the chemical sector, workers face daily exposure to hazardous substances, liquid spills, and corrosive chemicals. Choosing the right acid and alkali resistant safety shoes is not just a comfort issue—it’s a matter of safety and compliance. Proper footwear can prevent chemical burns, skin irritation, and long-term injuries, ensuring every worker stays protected on site.

1. Why the Chemical Industry Needs Specialized Safety Shoes

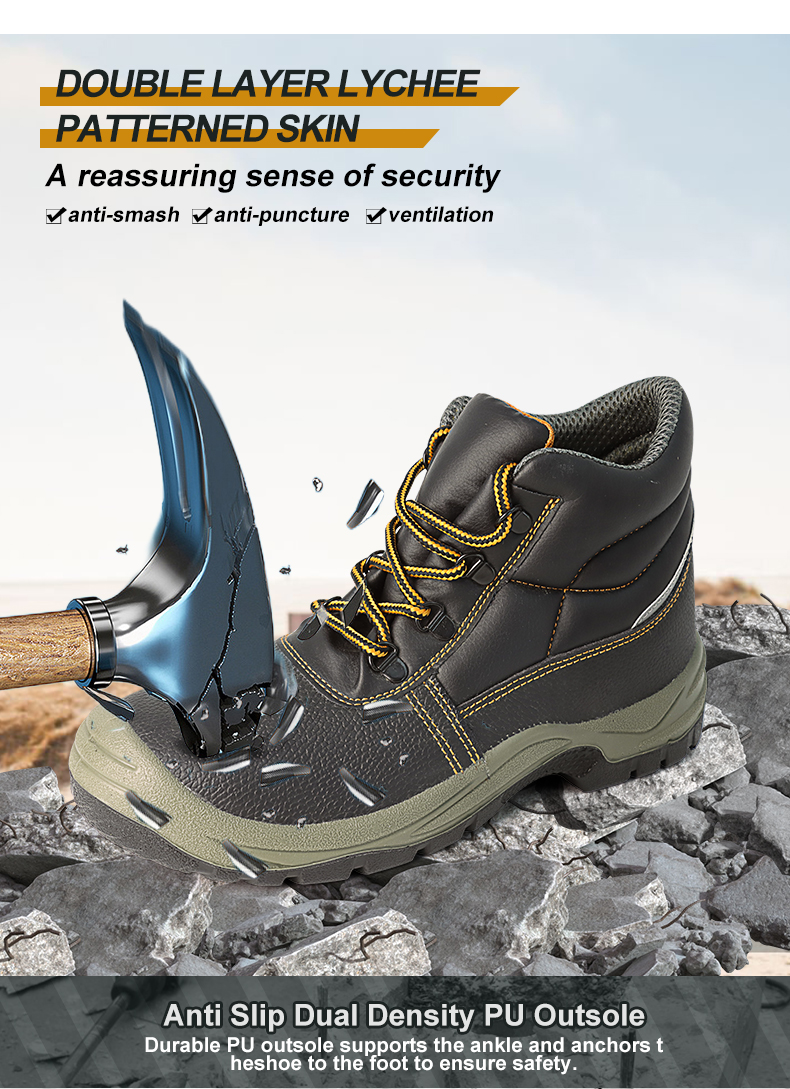

Unlike standard industrial footwear, acid and alkali resistant safety shoes are made with materials that prevent chemical penetration. In environments such as laboratories, chemical plants, or refineries, ordinary leather or fabric shoes can easily be damaged by acids, alkalis, or solvents.

Key protection features include:

-

Chemical-resistant uppers made from PU-coated leather or synthetic polymer.

-

Sealed seams to block liquid infiltration.

-

Non-porous outsoles that prevent absorption and corrosion.

Typical application: acid handling, cleaning chemicals, metal surface treatment, laboratory work.

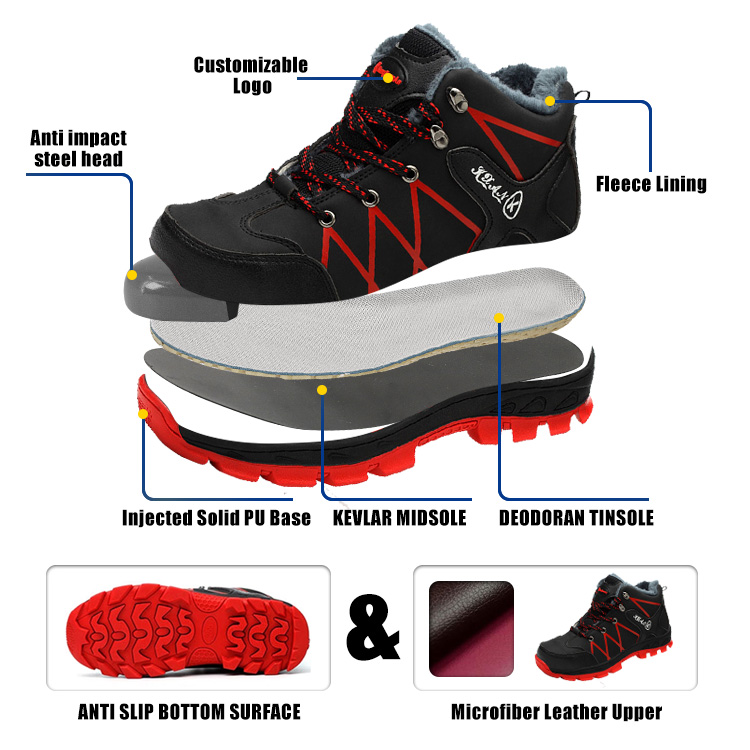

2. Material Guide: What Makes Safety Shoes Resistant

To guarantee safety and durability, acid and alkali resistant safety shoes should include:

-

PU or PVC uppers: resistant to acids, alkalis, and mild solvents.

-

Nitrile rubber soles: excellent for anti-slip and chemical resistance.

-

Anti-static lining: prevents sparks when working with flammable liquids.

-

Steel toe or composite toe cap: protects from mechanical impacts while maintaining chemical resistance.

3. Comfort and Ergonomics Still Matter

Even in high-protection footwear, comfort remains essential.

Modern acid and alkali resistant safety shoes should also feature:

-

Breathable inner lining to reduce sweat buildup.

-

Shock-absorbing midsoles to reduce foot fatigue during long shifts.

-

Lightweight construction to enhance movement in production areas.

Remember: a comfortable worker is a safe and productive worker.

4. Replacement Standards: When to Change Your Safety Shoes

Even the most durable acid and alkali resistant safety shoes have a lifespan.

Safety officers should follow these replacement guidelines:

-

Every 6–12 months under regular industrial use.

-

Immediately if cracks, discoloration, or surface corrosion appear.

-

After direct contact with strong acids or alkalis that cause visible damage.

-

Check soles regularly—if anti-slip performance declines, replace immediately.

Tip: Always keep an extra pair on-site for emergency replacement in chemical zones.

5. International Safety Standards

Ensure your acid and alkali resistant safety shoes comply with:

-

EN ISO 20345:2011 SRA/SRB/SRC – slip resistance and chemical protection.

-

ASTM F2413 – impact and compression resistance.

-

CE certification – proof of compliance for export and industrial supply.

Proper certification ensures that each pair provides consistent chemical and mechanical protection.

About Our Company – SAILGOOD Industrial Safety Footwear Manufacturer

Founded in 2013, SAILGOOD is a professional PPE manufacturer specializing in acid and alkali resistant safety shoes, protective gloves, and industrial workwear for chemical, construction, and oil & gas industries.

With advanced production technology, chemical-resistant materials, and international testing certifications, we supply global partners with high-quality protective footwear under OEM & ODM services.

Our mission is to deliver durable protection, comfort, and safety compliance for every industry.

Welcome to cooperate with SAILGOOD—we offer custom designs, samples, and global delivery for your private-label safety footwear projects.

Conclusion

In the chemical industry, the choice of acid and alkali resistant safety shoes directly affects worker safety and plant efficiency. By selecting certified, durable, and comfortable footwear—and replacing it at proper intervals—safety officers can ensure long-term protection against chemical hazards.

With SAILGOOD’s acid and alkali resistant safety shoes, your team can work confidently, safely, and productively, even in the toughest chemical environments.